Top-Quality Cunado Fittings: What You Need to Know Before Buying

When it comes to efficient plumbing, industrial piping, or construction projects, high-quality fittings are a cornerstone of success. Cunado fittings, known for their durability and reliability, have carved out a reputation in various industries. Whether you are an engineer, contractor, or DIY enthusiast, understanding the ins and outs of Cunado fittings is essential before making a purchase. This comprehensive guide will explore everything you need to know about Cunado fittings, including their types, uses, advantages, and tips for buying.

What Are Cunado Fittings?

Cunado fittings are components used to connect pipes or tubes in plumbing, industrial, or mechanical systems. Manufactured with precision engineering, these fittings ensure leak-proof connections, structural integrity, and efficient fluid or gas flow. Their application spans industries such as oil and gas, construction, automotive, and residential plumbing. Known for their quality and durability, Cunado fittings are trusted by professionals worldwide.

The uniqueness of Cunado fittings lies in their versatility. They are designed to accommodate different pipe materials, such as metal, PVC, and composite, and can withstand high pressures and temperatures. This makes them suitable for a wide range of challenging environments.

Types of Cunado Fittings: An Overview

Cunado fittings are available in a variety of types, each catering to specific needs. Below are some of the most common types:

1. Compression Fittings

Compression fittings are used to create secure joints in systems handling liquids and gases. They consist of a nut, a ferrule, and the fitting body, making them ideal for high-pressure applications.

2. Threaded Fittings

Threaded Cunado fittings have internal or external threads for creating strong connections. These are commonly used in pipelines where dismantling may be required for maintenance.

3. Flanged Fittings

Flanged fittings are used in industrial systems that require frequent inspections. The flanges are bolted together, ensuring a tight seal while allowing easy access.

4. Elbow Fittings

Elbow fittings redirect the flow of fluid or gas by 45 or 90 degrees. They are crucial for adjusting the pipeline layout without compromising functionality.

5. Tee and Cross Fittings

Tee fittings split the flow into two directions, while cross fittings divide it into four. These are essential for creating branch connections.

6. Couplers and Adapters

Couplers join two pipes of the same diameter, while adapters connect pipes of different sizes or materials.

Materials Used in Cunado Fittings

Cunado fittings are manufactured from various materials to cater to different applications. The most common materials include:

1. Stainless Steel

Stainless steel fittings are corrosion-resistant, durable, and suitable for harsh environments, such as marine and chemical industries.

2. Brass

Brass fittings are preferred for their resistance to rust and high conductivity, making them ideal for plumbing and gas systems.

3. PVC

PVC fittings are lightweight, affordable, and perfect for residential and low-pressure applications.

4. Carbon Steel

Carbon steel is known for its strength and is widely used in industrial and high-pressure applications.

5. Copper

Copper fittings are used in heating and cooling systems due to their excellent thermal conductivity.

Key Advantages of Using Cunado Fittings

1. Durability

Cunado fittings are built to last, withstanding high pressures, temperatures, and harsh environmental conditions.

2. Leak Prevention

Engineered with precision, Cunado fittings ensure tight seals, reducing the risk of leaks and minimizing maintenance needs.

3. Versatility

From residential plumbing to large-scale industrial projects, Cunado fittings cater to diverse requirements with a wide range of sizes and types.

4. Easy Installation

The design of Cunado fittings simplifies installation, reducing labor time and costs. Many types, such as compression fittings, require minimal tools.

5. Compliance with Standards

Cunado fittings meet international quality and safety standards, ensuring reliability in critical applications.

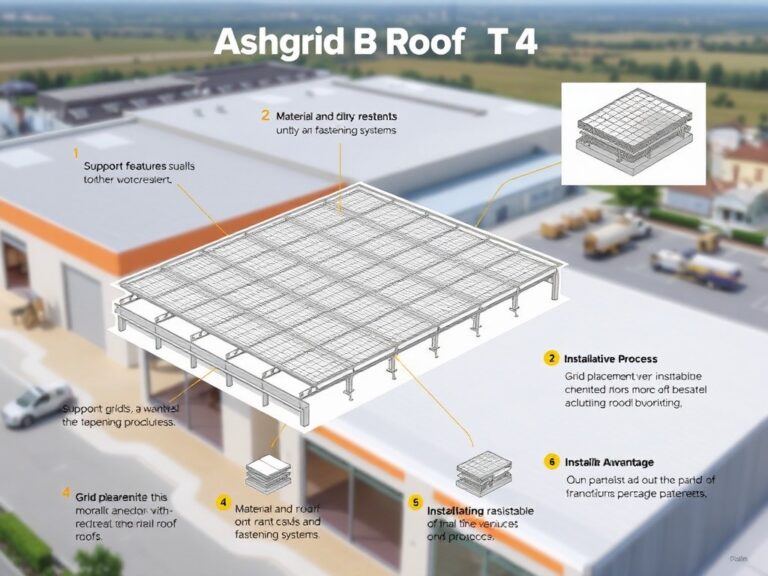

Applications of Cunado Fittings

Cunado fittings are indispensable in numerous industries. Below are some common applications:

1. Residential Plumbing

Cunado fittings are widely used in water supply systems, ensuring leak-proof and efficient connections in homes.

2. Industrial Piping

Industries like oil and gas rely on Cunado fittings for their robustness and ability to handle extreme pressures and temperatures.

3. HVAC Systems

In heating, ventilation, and air conditioning systems, Cunado fittings help maintain efficient flow and prevent energy loss.

4. Automotive

Cunado fittings are essential in automotive systems for fluid transmission, ensuring safety and performance.

5. Irrigation Systems

These fittings are also used in agriculture for constructing reliable irrigation pipelines.

Factors to Consider When Buying Cunado Fittings

To ensure you choose the right Cunado fittings for your project, consider the following factors:

1. Material Compatibility

Ensure that the fitting material matches the pipe material to avoid corrosion or failure.

2. Size and Dimensions

Accurate measurements are crucial to avoid mismatched fittings and ensure a proper fit.

3. Pressure and Temperature Ratings

Check the specifications to ensure the fittings can handle the operational pressures and temperatures of your system.

4. Application Requirements

Choose the fitting type based on the system’s function, such as whether it requires branching, directional changes, or couplings.

5. Compliance

Verify that the fittings comply with industry standards for safety and performance.

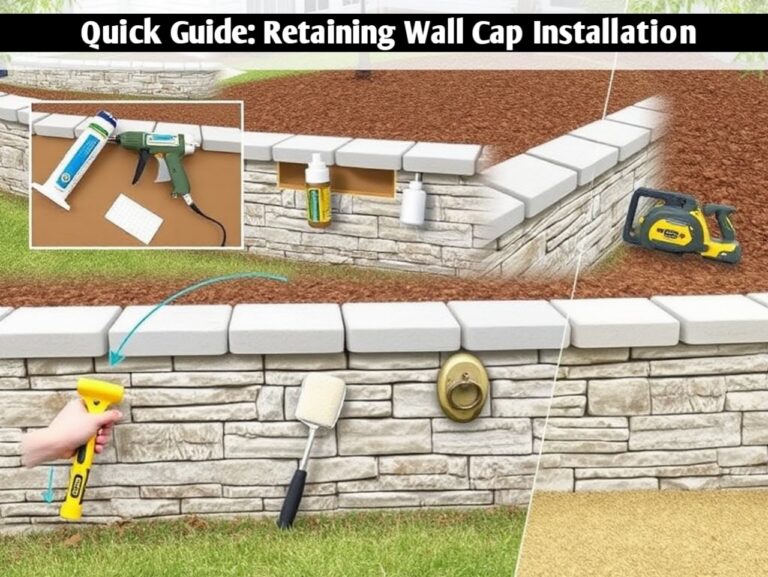

How to Install Cunado Fittings Correctly

Installing Cunado fittings correctly is essential to ensure their performance and longevity. Here are some tips:

1. Clean the Pipes

Ensure that the pipes are clean and free from debris before installation to achieve a tight seal.

2. Use Proper Tools

Use the appropriate tools for each type of fitting to avoid damage during installation.

3. Follow Manufacturer Instructions

Always follow the manufacturer’s guidelines to ensure proper installation and warranty coverage.

4. Test for Leaks

After installation, test the system for leaks to ensure all connections are secure.

Maintenance Tips for Cunado Fittings

Proper maintenance can extend the lifespan of your Cunado fittings. Follow these tips:

1. Regular Inspections

Check for signs of wear, corrosion, or leaks, especially in high-pressure systems.

2. Timely Replacement

Replace damaged or worn-out fittings promptly to prevent system failure.

3. Avoid Over-Tightening

Over-tightening can damage the threads or distort the fitting, leading to leaks.

Where to Buy High-Quality Cunado Fittings

Purchasing Cunado fittings from reputable suppliers ensures you receive genuine products that meet quality standards. Look for distributors who offer:

- Wide Selection: Ensure the supplier stocks various types and sizes.

- Competitive Pricing: Compare prices across suppliers to get the best deal.

- Customer Support: Choose suppliers who provide expert advice and after-sales support.

- Certifications: Verify that the fittings are certified to meet industry standards.

Conclusion: Why Cunado Fittings Are Worth the Investment

Cunado fittings stand out as a reliable choice for anyone involved in plumbing, industrial piping, or related fields. Their durability, versatility, and ease of use make them a preferred option in demanding applications. By understanding the types, materials, and installation processes, you can make informed decisions that ensure long-term success for your projects. Whether you are upgrading a plumbing system or designing an industrial pipeline, Cunado fittings provide the quality and performance you can trust.

Read Also Our This Post: A Guide to Choosing the Best 12mm White Ceramic Filter Tip

Kamran Khatri is a versatile writer and editor at ExpressZone.co.uk, bringing fresh perspectives and insightful commentary across a wide range of topics. With a passion for exploring diverse subjects—from technology, business, and finance to lifestyle, travel, and the arts—Kamran aims to inform, inspire, and engage readers through well-researched articles and thought-provoking content.

His work spans multiple categories including health, education, pets, entertainment, real estate, and sustainability, reflecting his commitment to delivering knowledge that connects with everyday life. Whether breaking down the latest trends, sharing practical tips, or highlighting cultural insights, Kamran’s writing combines clarity with creativity.

When he’s not crafting stories for ExpressZone.co.uk, Kamran enjoys keeping up with global developments, exploring innovative ideas, and connecting with readers who share his curiosity about the world.